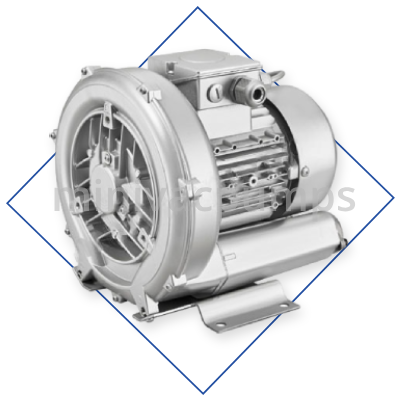

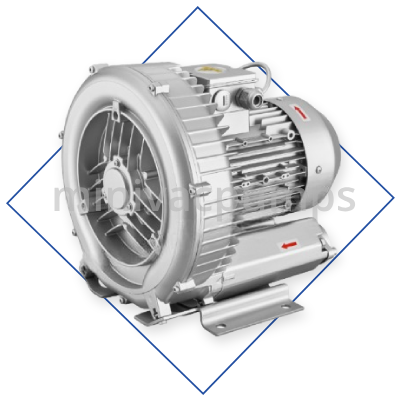

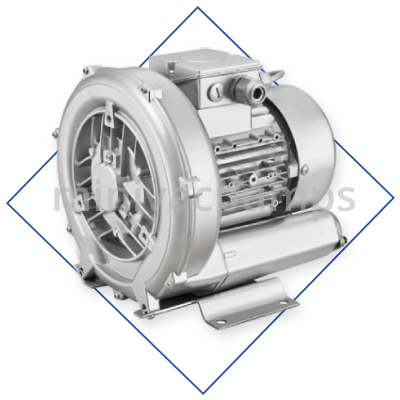

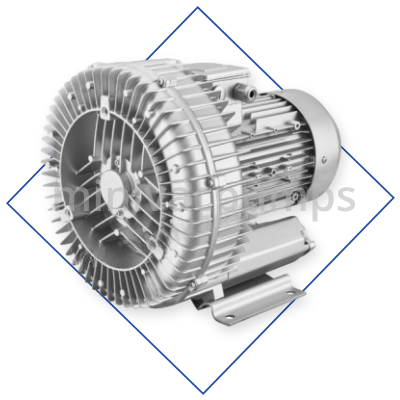

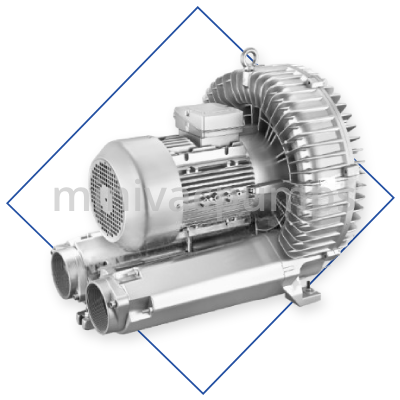

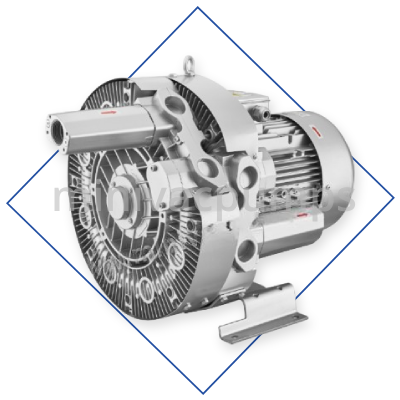

Side Channel Vacuum Pumps and Compressors

Principle Working

Side channel vacuum pumps & Compressors, also known as regenerative blowers or Ring Blowers, operate on a unique principle of regenerative compression. The impeller inside the pump rotates, generating a high-velocity gas flow that creates alternating areas of low and high pressure within the side channel. As the gas molecules move through the side channel, they experience multiple stages of compression and expansion, resulting in efficient compression and continuous flow of gas or air

This regenerative process imparts significant energy to the gas, allowing side channel vacuum pumps to achieve high vacuum levels and pressure differentials without the need for oil or lubrication. The absence of contact between moving parts ensures minimal wear, resulting in low maintenance and extended pump life.

We are Manufacturer, Exporter and Supplier of Ring Vacuum Blowers & Vacuum Pumps

Applications

Minivac Side Channel Vacuum Pumps & Compressors find widespread applications across various industries, where their unique capabilities meet critical demands. Some key application areas include:

Industrial Vacuum Systems

Side channel vacuum pumps excel in creating robust industrial vacuum systems, contributing to material handling, packaging, and product transfer applications. Their ability to handle a wide range of gases and vapours makes them an ideal choice for diverse industrial environments.

Aeration and Agitation

In wastewater treatment plants and aquaculture facilities, side channel vacuum pumps play a vital role in providing aeration and agitation for biological processes. Their reliable and continuous operation ensures efficient oxygen transfer, supporting optimal treatment and growth conditions.

Drying and Dehydration

Side channel vacuum pumps are widely used in drying and dehydration processes, facilitating the removal of moisture and other volatile substances from materials, such as food products, chemicals, and pharmaceuticals.

Pneumatic Conveying

Side channel vacuum pumps are indispensable in pneumatic conveying systems, enabling the transfer of bulk materials efficiently and with minimal energy consumption.

Printing and Paper Handling

In the printing industry, side channel vacuum pumps aid in paper handling, ensuring precise and consistent feeding of paper sheets during the printing process.

Environmental Applications

These pumps find application in various environmental processes, including soil vapor extraction, landfill gas recovery, and vapor recovery systems.

Why Choose Minivac Side Channel Vacuum Pumps & Compressors (Ring Blowers)

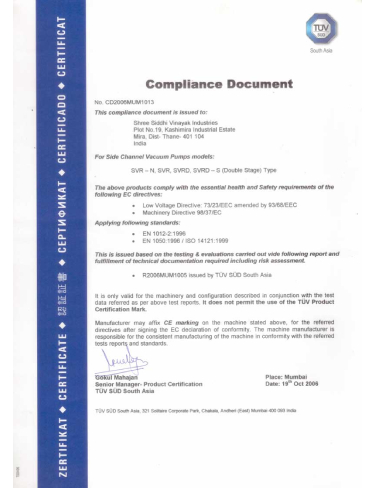

When you choose Minivac Side Channel vacuum pumps, you gain access to cutting-edge technology and exceptional performance. Our pumps are meticulously engineered to deliver consistent and reliable operation, even in demanding industrial environments.

With a focus on quality, our side channel vacuum pumps are manufactured using top-grade materials and undergo rigorous testing to ensure compliance with the highest industry standards. Their compact design, energy efficiency, and low noise levels make them an environmentally conscious choice for your vacuum needs.

At Shree Siddhivinayak Industries, we pride ourselves on providing exceptional customer service and technical support. Our team of experts is dedicated to understanding your unique requirements and recommending the best-fit vacuum solutions for your applications.

Conclusion

Experience the power of regenerative compression with Minivac Side Channel vacuum pumps. Combining efficiency, reliability, and versatility, our pumps elevate your industrial processes and ensure optimal performance for a wide range of applications.

Whether you require vacuum solutions for material handling, aeration, or drying, Minivac Side Channel vacuum pumps are your trusted partners in achieving excellence. Join the league of satisfied customers who have relied on our vacuum expertise for over two decades. Get in touch with us today to explore how our side channel vacuum pumps can revolutionize your vacuum applications.