Plastic

Advancing Plastic Manufacturing with Vacuum Technology

Welcome to Shree Siddhivinayak Industries, your premier destination for cutting-edge vacuum pump solutions. With over three decades of experience and a profound understanding of vacuum technology, we are excited to highlight the critical role of vacuum pumps in the laboratory equipment industry. Our exceptional range of vacuum pumps is engineered to cater to the unique demands of laboratories, driving precision, reliability, and breakthrough discoveries in scientific research

Experience the transformative potential of vacuum pumps in the plastics industry. At Shree Siddhivinayak Industries, we take pride in offering a comprehensive range of high-quality vacuum pumps designed to cater to the unique demands of plastics manufacturing.

Our cutting-edge solutions empower plastics professionals with reliable, efficient, and precision-driven vacuum technology. Together, we can shape a future where plastics manufacturing embraces sustainability, innovation, and the highest standards of quality.

Contact us today to explore how our vacuum pumps can elevate your plastics manufacturing processes and drive your business forward.

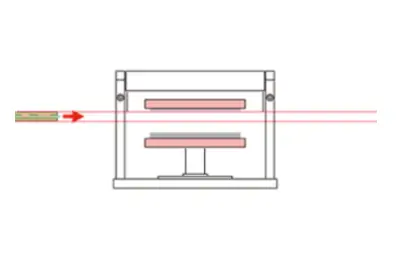

Plastic Extrusion

For: Enhancing Production Efficiency

Vacuum pumps are integral to the plastic extrusion process, where they aid in the efficient and uniform cooling of extruded plastic products. By creating a vacuum within the cooling tanks, vacuum pumps rapidly remove heat from the plastic, facilitating quick solidification. This ensures the production of high-quality, dimensionally stable plastic products with consistent shapes and dimensions.

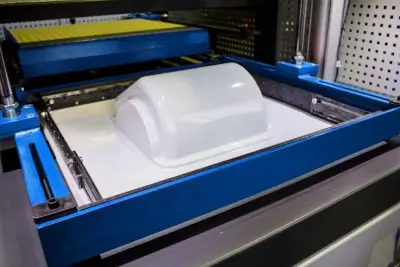

Thermoforming and Vacuum Forming

For: Shaping the Future

In thermoforming and vacuum forming processes, vacuum pumps play a vital role in shaping plastic sheets into intricate moulds. By applying vacuum pressure, these pumps draw the heated plastic sheet tightly against the mould, ensuring accurate replication of complex shapes. This technology is widely used in packaging, automotive, and various consumer goods industries.

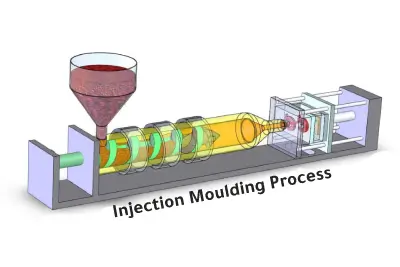

Plastic Injection Moulding

For: Precision and Reproducibility

Vacuum pumps are crucial in plastic injection moulding processes, enabling the removal of trapped air and gases from the mould cavity. This ensures the production of defect-free and high-precision plastic parts. Vacuum-assisted moulding enhances product consistency and minimizes imperfections, contributing to cost-effective and reliable mass production.

Plastic Recycling

For: A Sustainable Approach

In the realm of plastic recycling, vacuum pumps aid in the extrusion and processing of recycled plastic materials. By creating the required vacuum environment, these pumps remove moisture and volatile contaminants from the recycled plastic, ensuring the production of clean and high-quality recycled plastic products.

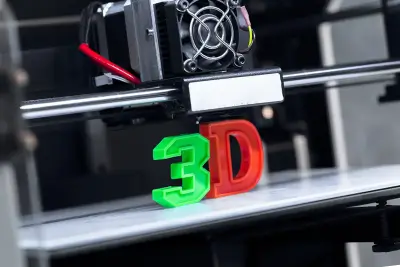

3D Printing

For: Precision Additive Manufacturing

Vacuum pumps are also utilized in the realm of 3D printing, supporting the removal of air bubbles and maintaining a stable atmosphere within the printing chamber. This enhances print accuracy and prevents deformations, contributing to the production of intricate and high-quality 3D-printed plastic components.

Vacuum Lamination

For: Ensuring Adhesion Perfection

In vacuum lamination processes, vacuum pumps assist in achieving optimal adhesion between plastic layers and substrates. By removing air and ensuring even pressure distribution, vacuum pumps contribute to a strong bond and enhance the overall structural integrity of laminated plastic products.